The evolution of safety standards in hydrogen energy storage and transportation has been a critical enabler for the growing adoption of this clean energy carrier. As hydrogen gains traction in sectors ranging from automotive to industrial applications, the frameworks governing its safe handling have undergone significant refinement. These changes reflect both technological advancements and lessons learned from real-world deployments.

In the early days of hydrogen utilization, safety protocols were largely adapted from those used for natural gas and other flammable substances. This approach, while pragmatic, failed to account for hydrogen's unique properties, such as its low ignition energy, wide flammability range, and tendency to embrittle certain materials. The first generation of hydrogen-specific standards emerged in response to several high-profile incidents that highlighted these distinctive risks. These initial regulations focused primarily on preventing leaks and mitigating explosion hazards in stationary storage systems.

The transportation sector became the next frontier for safety standardization as hydrogen fuel cell vehicles began entering commercial markets. Unlike stationary storage, vehicular applications introduced dynamic challenges including vibration, crash scenarios, and frequent pressure cycling. Regulatory bodies responded by developing performance-based standards that specified safety outcomes rather than prescribing specific technologies. This shift allowed for innovation in tank design and materials while maintaining rigorous safety benchmarks.

Recent years have seen the safety paradigm expand beyond physical hazards to encompass system-wide risk management. Modern standards now address the entire hydrogen value chain, from production through end-use. This holistic approach considers not just immediate operational risks but also long-term material durability, maintenance protocols, and even cybersecurity concerns for digitally monitored systems. The International Organization for Standardization (ISO) and other bodies have played pivotal roles in harmonizing these requirements across jurisdictions.

Material science breakthroughs have continuously reshaped safety standards. The certification of composite pressure vessels marked a watershed moment, enabling lighter-weight storage with enhanced safety margins. Similarly, the development of hydrogen-compatible elastomers and advanced leak detection technologies has allowed for more stringent performance requirements. Standards have evolved in parallel to validate these innovations while ensuring they don't compromise safety.

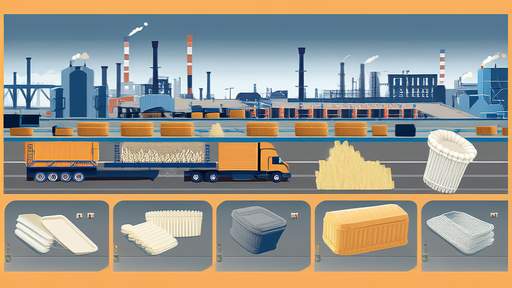

Large-scale hydrogen infrastructure projects have served as proving grounds for safety concepts. The lessons from these deployments have driven iterative improvements in standards, particularly regarding bunkering operations, pipeline transmission, and bulk storage facilities. Emergency response protocols have received particular attention, with updated standards mandating specialized training for first responders and improved safety interlocks at refueling stations.

Looking ahead, the safety standards framework continues to adapt to emerging applications such as hydrogen-powered aviation and maritime transport. These sectors introduce novel challenges including cryogenic storage, rapid refueling requirements, and operation in confined spaces. The standards development process has become more anticipatory, with working groups proactively addressing safety considerations for technologies still in the demonstration phase.

The globalization of hydrogen trade is fostering greater international alignment in safety standards. While regional differences persist—often reflecting varying regulatory philosophies or climate conditions—there's growing recognition that common benchmarks facilitate technology transfer and supply chain development. This convergence is particularly evident in standards governing hydrogen quality for fuel cell applications and safety certifications for transport equipment.

Digitalization is introducing new dimensions to hydrogen safety. Modern standards increasingly incorporate requirements for real-time monitoring systems, data logging, and predictive maintenance capabilities. These provisions aim to prevent incidents through early anomaly detection while providing robust forensic tools for post-incident analysis. The integration of IoT technologies with hydrogen infrastructure is driving continuous updates to cybersecurity provisions within safety standards.

The relationship between standards development and public perception has become increasingly important. Regulatory bodies now recognize that beyond technical adequacy, safety standards must inspire confidence among communities hosting hydrogen facilities. This has led to greater emphasis on transparent risk communication frameworks within the standards themselves, as well as more inclusive stakeholder engagement processes during their formulation.

As hydrogen assumes a central role in decarbonization strategies worldwide, its safety standards will continue evolving in sophistication and scope. The next frontier may involve standards for hydrogen-natural gas blends in existing pipelines or protocols for large-scale underground storage. What remains constant is the delicate balance between enabling innovation and ensuring uncompromising safety—a challenge that standards developers will continue navigating as the hydrogen economy matures.

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025