The global push toward decarbonization has placed carbon capture technologies at the forefront of climate mitigation strategies. Over the past decade, significant advancements have been made in reducing the costs associated with these systems, making them increasingly viable for large-scale deployment. What was once considered a prohibitively expensive solution is now showing signs of becoming an economically feasible tool in the fight against climate change.

Early Challenges and High Costs

When carbon capture and storage (CCS) first emerged as a potential solution, the technology faced substantial financial barriers. Early projects required massive capital investments, with costs often exceeding $100 per ton of CO2 captured. The complexity of separating CO2 from industrial emissions, compressing it, and transporting it to storage sites contributed to these exorbitant prices. Many energy experts dismissed CCS as impractical, arguing that renewable energy sources offered a more cost-effective path to reducing emissions.

Pilot projects in the 2000s and early 2010s struggled with inefficiencies, particularly in the energy-intensive capture process. The parasitic load—the amount of energy diverted from power generation to operate CCS systems—often reached 20-30% of a plant's total output. This not only drove up operational costs but also reduced the overall efficiency of facilities implementing the technology. Skepticism grew as several high-profile projects were canceled due to budget overruns and technical difficulties.

The Turning Point: Learning by Doing

Around 2015, a noticeable shift began occurring as operational experience accumulated. Engineers and researchers identified optimization opportunities through real-world applications. Small design improvements—such as more efficient solvent formulations in post-combustion capture and better membrane materials—started yielding significant cost reductions. The concept of "learning by doing" proved particularly valuable, with each new project contributing knowledge that could be applied to subsequent installations.

Perhaps the most crucial development came from the oil and gas industry, where CO2 injection for enhanced oil recovery created an unexpected revenue stream. This economic incentive helped offset capture costs and demonstrated how carbon utilization could improve the business case for CCS. Simultaneously, governments began implementing more robust carbon pricing mechanisms and tax credits, further improving the financial viability of these projects.

Technological Breakthroughs Driving Down Expenses

Recent years have witnessed remarkable technological progress across all components of carbon capture systems. Novel solvent chemistries have reduced energy requirements by up to 40% compared to first-generation technologies. Solid sorbents and metal-organic frameworks (MOFs) show promise for even greater efficiency gains in the coming decade. Meanwhile, advancements in compression and pipeline transportation have decreased midstream costs substantially.

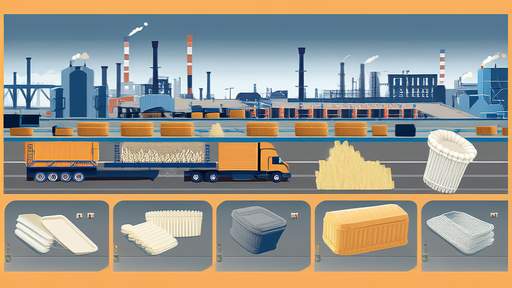

Modular construction techniques borrowed from the liquefied natural gas (LNG) industry have brought down capital expenditures. Instead of building massive, custom-designed capture facilities, companies can now deploy prefabricated units that achieve economies of scale through standardized production. This approach has been particularly transformative for smaller industrial emitters that previously couldn't justify CCS investments.

The Role of Policy and Market Mechanisms

Government support has played a pivotal role in accelerating cost reductions. The U.S. 45Q tax credit, Canada's Carbon Capture, Utilization and Storage Investment Tax Credit, and similar initiatives in Europe have created more stable investment environments. These policies have helped de-risk projects and attract private capital, leading to larger deployments that further drive down costs through scale effects.

Carbon markets have also matured significantly. As emission trading systems expand and carbon prices rise in jurisdictions like the EU, the economic case for capture technologies strengthens. Perhaps more importantly, corporate net-zero commitments have created demand for carbon removal credits, opening new financing avenues for CCS projects through voluntary carbon markets.

Current Cost Trajectories and Future Projections

Today, leading CCS projects report capture costs in the $40-60 per ton range for industrial applications, with some optimized systems achieving even lower figures. The most recent cost analyses suggest that with continued deployment and technological refinement, $30-40 per ton may become achievable by 2030 for certain emission sources. Direct air capture—while still more expensive—has seen its costs drop from $600 per ton to around $250-300 per ton in advanced systems.

Industry analysts point to several factors that could further accelerate cost declines. Increased competition among technology providers, standardization of equipment, and the development of shared CO2 transport and storage infrastructure all contribute to a favorable outlook. The growing hydrogen economy may provide additional momentum, as blue hydrogen production inherently requires carbon capture.

Regional Variations and Sector-Specific Trends

Cost reduction patterns aren't uniform across all regions or industries. Areas with favorable geology for CO2 storage, existing pipeline networks, and supportive policies tend to see faster cost declines. The U.S. Gulf Coast, North Sea region, and Middle East have emerged as particularly attractive locations for CCS deployment due to these factors.

Industrial sectors show varying cost reduction trajectories as well. Cement and steel production—where process emissions are harder to abate through other means—have seen particularly sharp cost improvements in capture technologies. Power generation applications, while making progress, still face steeper challenges due to the dilute nature of flue gas from coal and gas plants.

Remaining Challenges and Critical Uncertainties

Despite the encouraging trends, significant hurdles remain. Storage site characterization and permitting continue to cause delays and add costs to projects. Public acceptance issues, particularly regarding CO2 pipelines, have emerged as unexpected obstacles in some regions. The intermittent nature of renewable energy integration also poses questions about how to optimize capture systems for flexible operation.

The ultimate cost floor for carbon capture remains uncertain. While further reductions appear likely, physical and thermodynamic limits will eventually constrain how cheap the technology can become. This makes continued investment in alternative solutions essential, even as CCS becomes more affordable.

The Path Forward

Looking ahead, the carbon capture industry appears poised for exponential growth. Project pipelines have swollen to over 300 million tons per year of potential capacity worldwide. As these projects come online and operational experience deepens, additional cost reductions seem inevitable. The technology's role in climate mitigation strategies will likely expand accordingly.

What began as an expensive, niche technology has transformed into a credible tool for decarbonizing challenging sectors. While not a silver bullet, carbon capture's improving economics suggest it will play an important part in the global effort to achieve net-zero emissions. The coming decade will prove critical in determining just how far costs can fall and how widely these systems can be deployed.

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025

By /Jun 3, 2025